Food safety is a major concern for consumers and manufacturers. The demand for fresh, nutritious, and safe food products is increasing. High-pressure thermal sterilization (HPTS) has emerged as an innovative technology to meet these expectations. This method combines high pressure and heat to sterilize food without compromising its taste, texture, or nutritional value.

What Is High-Pressure Thermal Sterilization?

HPTS is a process that eliminates harmful microorganisms in food. It uses a combination of high pressure (up to 600 megapascals) and moderate heat (80–120°C). Unlike traditional sterilization methods, HPTS reduces the need for excessive heat. This prevents overcooking and retains the food’s quality.

The process works by disrupting the cellular structures of bacteria, yeasts, molds, and viruses. High pressure damages their membranes and proteins, making them inactive. Meanwhile, heat accelerates this effect, ensuring complete sterilization.

Benefits of HPTS

High-pressure thermal sterilization offers several advantages over conventional methods:

- Better Preservation of Nutritional Value

Foods treated with HPTS retain their vitamins, minerals, and antioxidants. Traditional heat sterilization often causes nutrient loss due to prolonged exposure to high temperatures. - Improved Flavor and Texture

Since HPTS minimizes thermal degradation, the natural flavors and textures of food are preserved. For example, fruit juices treated with HPTS taste fresher than those processed with traditional heat methods. - Extended Shelf Life

HPTS effectively eliminates pathogens and spoilage microorganisms, extending the shelf life of food products. This reduces food waste and helps manufacturers meet market demands for longer-lasting products. - Reduced Use of Preservatives

With HPTS, the need for chemical preservatives decreases. Consumers prefer fewer additives, making HPTS-treated foods more appealing.

Applications of HPTS

HPTS is suitable for a wide range of foods, including:

- Ready-to-Eat Meals: These meals often have high microbial loads. HPTS ensures they remain safe for consumption while maintaining quality.

- Juices and Beverages: The process helps retain the natural flavors and colors of drinks.

- Meat and Seafood: HPTS ensures these products remain free of pathogens like Salmonella and Listeria.

- Dairy Products: Milk, yogurt, and cheese benefit from this method, as it keeps their taste and texture intact.

Challenges of Adopting HPTS

Despite its benefits, high-pressure thermal sterilization faces some challenges:

- High Initial Investment

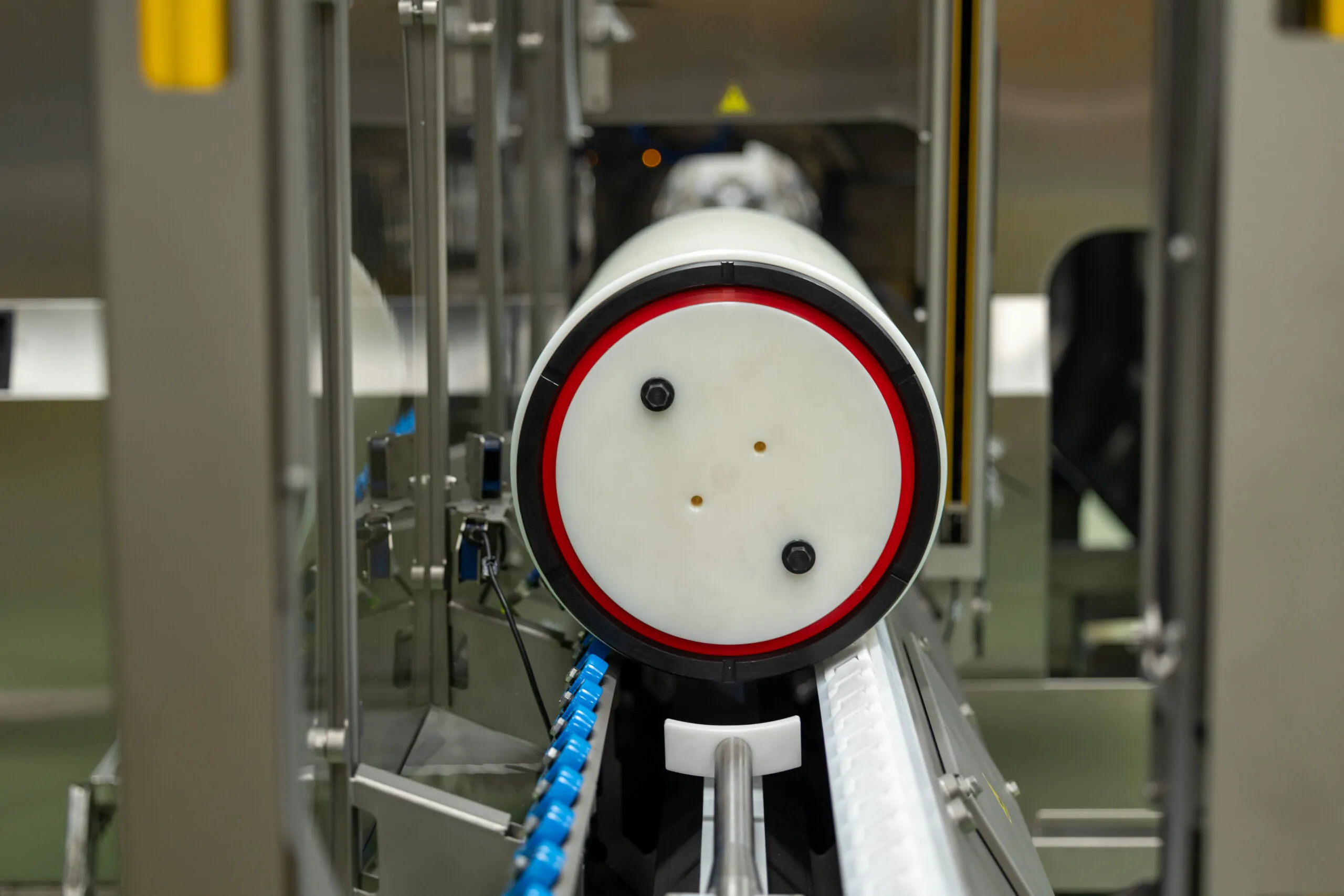

The equipment required for HPTS is expensive. Small and medium-sized businesses may find it difficult to adopt this technology. - Specialized Knowledge

Operators need training to manage HPTS systems effectively. This includes understanding pressure levels, temperature controls, and safety protocols. - Limited Packaging Options

HPTS works best with flexible and water-resistant packaging materials. Manufacturers must ensure compatibility with their existing products.

The Future of HPTS

The adoption of high-pressure thermal sterilization is growing. As technology advances, the cost of equipment is likely to decrease. This will make HPTS more accessible to manufacturers of all sizes.

Additionally, consumers are demanding healthier, minimally processed foods. HPTS aligns perfectly with these preferences. Its ability to ensure food safety while preserving quality makes it a promising solution for the food industry.

Final Thoughts

High-pressure thermal sterilization is changing how we process and preserve food. It offers a safer and more efficient alternative to traditional methods. With its ability to retain nutrients, improve taste, and reduce preservatives, HPTS is shaping the future of food manufacturing.

For businesses looking to improve their processes, HPTS provides a way to deliver high-quality products that consumers trust. As this technology continues to evolve, it is set to play a vital role in enhancing food safety and quality worldwide.